Description

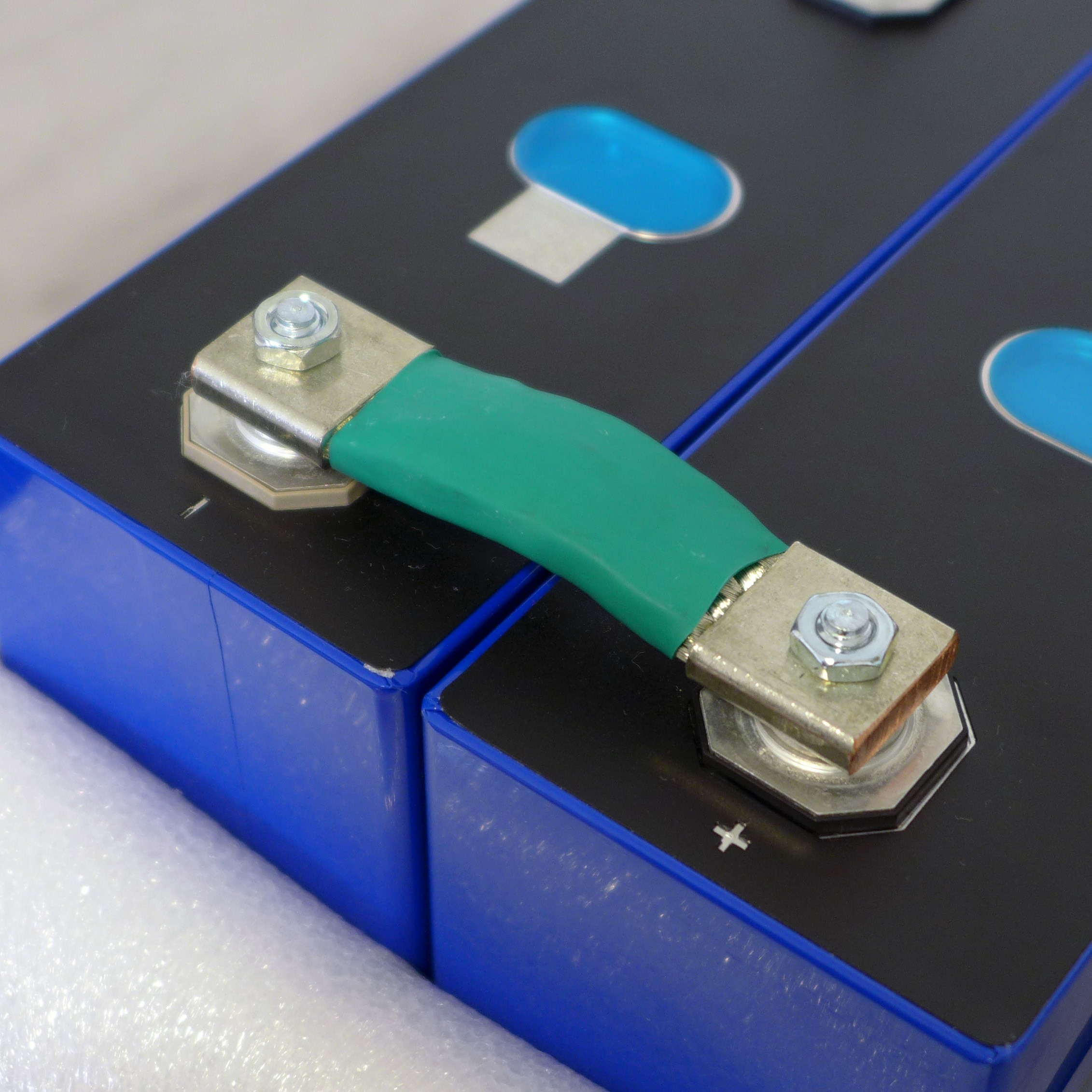

- Flexible, insulated connectors (busbars) for LiFePO4 cells.

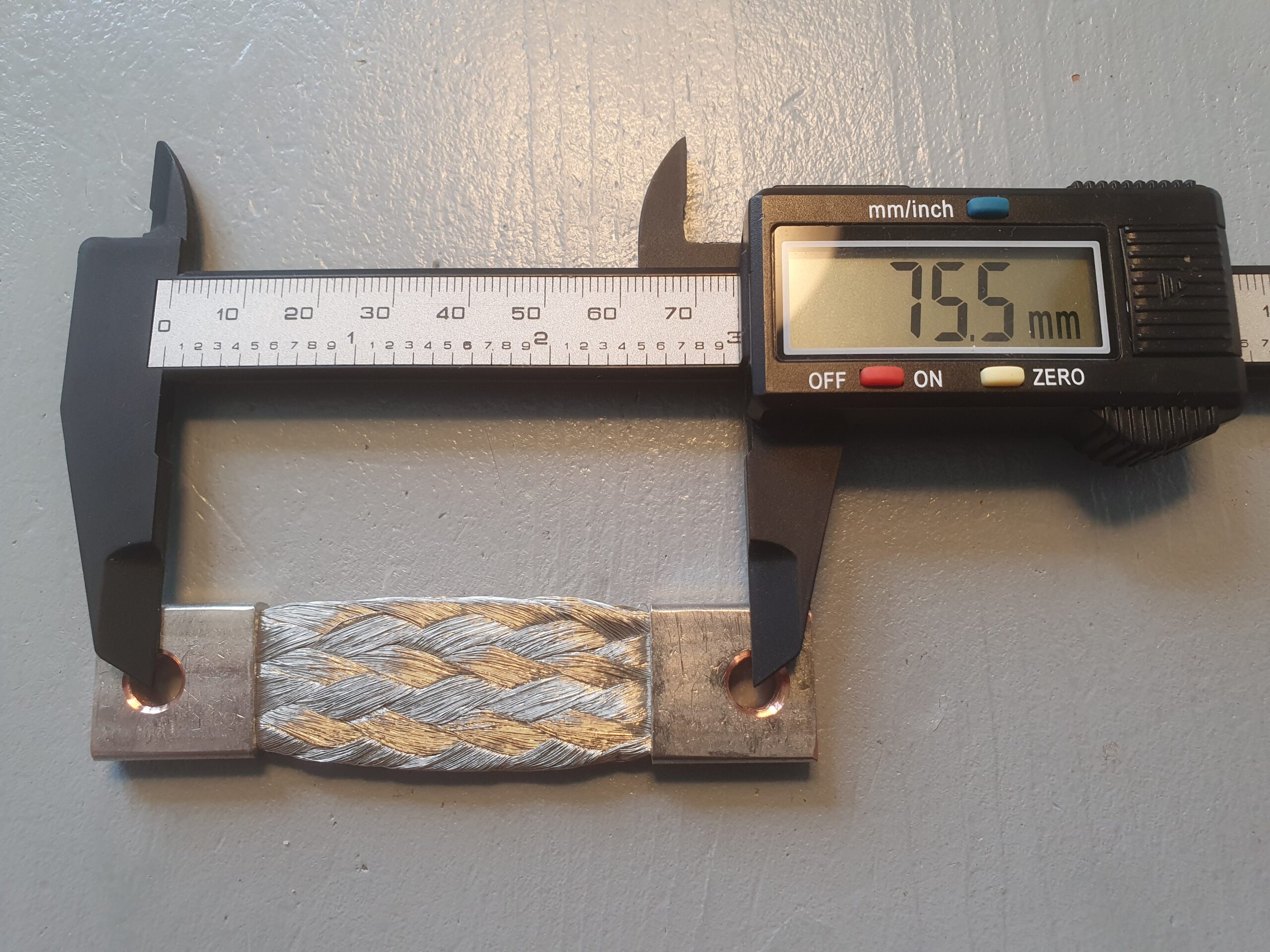

- Cell connectors up to 300A (6mm thickness).

- DIY power storage with cells from 230Ah to 310Ah. EVE, CATL.

-

Copper busbars for 48V, 24V, or 12V batteries.

Product highlights:

- Fits all cells with M6 thread.

- The lithium busbars are flexible and insulated.

- Protects the cells during later expansion. The power storage is safeguarded.

- Large contact surface through properly sized M6 hole. Very low resistance.

- Made from high-quality copper wire, zinc-plated for corrosion protection.

- Copper content 99.95%.

- Sufficient tolerance for possible cell expansion.

- Also suitable for compressed 230Ah cells.

- 12V (4 LFP cells) and 24V (8 LiFePO4 cells) for camping, boat, caravan batteries, and 48V for DIY solar storage systems.

High-quality copper cell connectors for DIY power storage with LFP (LiFePO4) cells from 230Ah to 310Ah from e.g. CATL, EVE (EVE LF280-K), LG Chem, Panasonic, BYD, SK Innovation, Samsung SDI, CALB and Gotion High-tech etc.

Lithium busbars for solar storage with 16 cells (15 connectors), 8 cells (7 connectors) or 4 cells (3 connectors). Often together with a Daly BMS, JKBMS and connected to a Victron Multiplus inverter.

LiFePO connection rail in the highest quality. Cell connectors can withstand up to 300A (6mm thick).

Christian –

Very good busbars.. prompt delivery! Highly recommended.

Amazon Kunde –

Very good busbars.. prompt delivery! Highly recommended

michi199930 –

Great product.

High-quality finish.

Easy to install with the supplied flat nuts.

Surely 4x as strong as the supplied ones.

A. Wenzel –

These connectors are of high quality. The connectors that came with my EVE 280Ah cells are a joke in comparison. Highly recommended for any DIY LiFePO4 home storage!

H v d B –

LIFEPO4 batteries are rectangular and are usually placed directly next to each other and glued or connected with compression bands. However, they expand when the temperature rises and pull on the connectors between the cells, which can cause the terminals to be damaged or even partially pulled out of the battery body. Especially when batteries get older, some gas forms inside, causing the batteries to expand a little more. They still work well but are often a few millimeters thicker.

Therefore, it is better to equip battery packs with flexible connectors. These connectors have enough play to allow for expansion. The cable lugs are massive and can definitely handle 300A. The copper terminal plates are cleanly connected to the cables and flush.

Clear purchase recommendation. Every large battery pack should be equipped with such connectors for protection.

Armin –

After the purchase, a short summary from my side:

Measured values from 0.14 to 0.12mOhm per connector at the pole!

All assembled and mounted with graphite conductive paste and 5Nm.

Of course, both contact surfaces were cleaned and degreased beforehand with abrasive fleece.

I measured an amazing value of under 4mOhm across the entire pack. That is (in my opinion) more than OK.

If I subtract the cell’s internal resistance from the first charging cycle (0.16mOhm, 16S = 2.56mOhm), about ~1.44mOhm remain across 15 connectors. Only 0.095mOhm is lost per connector – that’s a good improvement over the supplied connectors.

A load test will take a little longer, but I am confident… I’m more than satisfied and honestly didn’t expect it.??

K Jakobsen –

The item is as described and in good condition.

Steffen –

Top busbars. Significantly better than the simple ones that come with the cells. I’ve already installed them several times. I’ve personally tested them on cells from 230Ah to 315Ah. Tip: pre-bend them accordingly before installation.

Steffen –

I bought 48 pieces of the 300A busbars (for 3 17S packs). These are well made and fit the typical prismatic cells without issue. If you use only 0.5mm thick epoxy plates, you need to compress the busbar a bit – but they handle this without any problems. It’s good that if you insert a 2-3mm thick insulation between the cells, they are still easy to mount. For some rigid busbars, this would no longer be possible. Thanks to the braided design, these busbars simply ‘breathe’ with the cells when they move mechanically.

A top concept! Would buy again!